Single axis scanning stages

PM-1

Scanning Stages

We’ve made it easy to purchase these kits by making them available online through our distribution partnership with Motion Plus.

An easy way to add motion to your measurement process

Do you need to scan your sensor over your part’s surface to capture area or profile data? Our single axis stage kits offer a quick and easy way to integrate your sensor with motion control.

Get it fast

Need something soon? Quick ship motorized stages are available to meet your project timelines.

Out-of-the-box

Don't have the in-house capabilities or time to select and implement the right motion control equipment? We supply all of the necessary hardware to get you up and running quickly.

No compromises

The entire PM-1 platform is designed to maintain all sensor specifications. Don’t settle for noisy or degraded data - purchase with confidence that your sensor will perform as advertised.

Easy to use

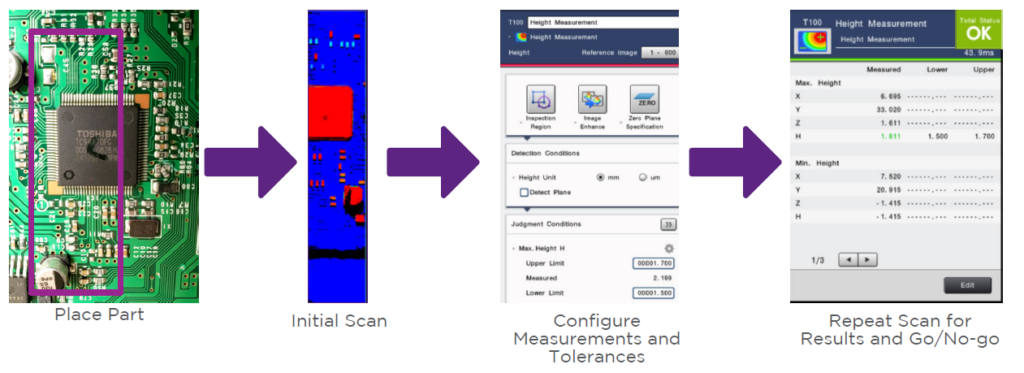

Get “go/no-go” results with a literal push-of-a button! It really is that easy - one button push triggers motion, data collection, data analysis, and resets stage position for the next scan.

Configurations

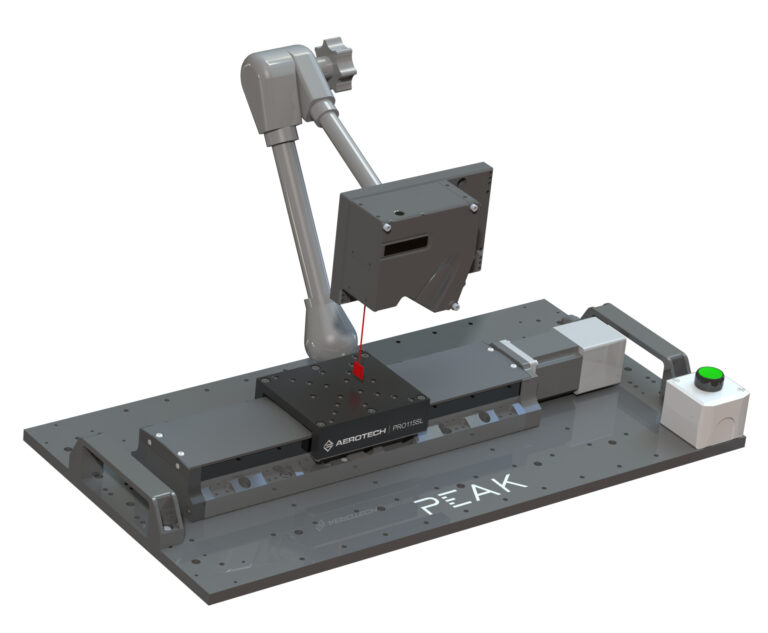

Moving part, fixed sensor

This is the most common configuration. The part moves on the motorized stage and the sensor remains fixed above.

- Adjustable arm sets the sensor's focal height

- Linear stage scans the part length specified by the operator

- Sensor remains stationary as the scan takes place

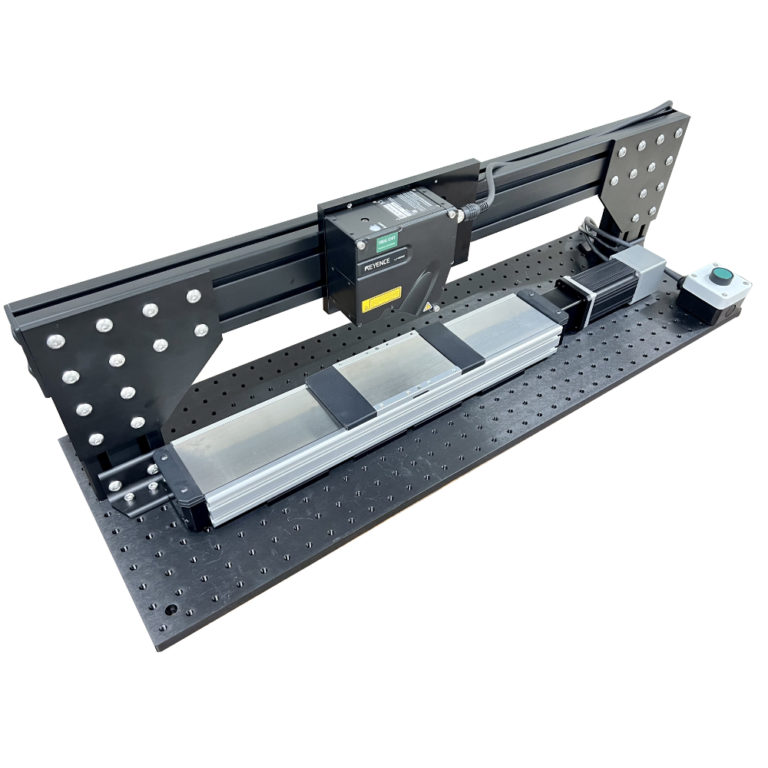

Moving sensor, fixed part

Sometimes it makes more sense to move the sensor and not the part being scanned. The sensor can be mounted directly to the motorized stage in these cases.

- Ideal for large or heavy parts

- Can be added in-line with other equipment

- Uses the same controls as the fixed sensor configuration above

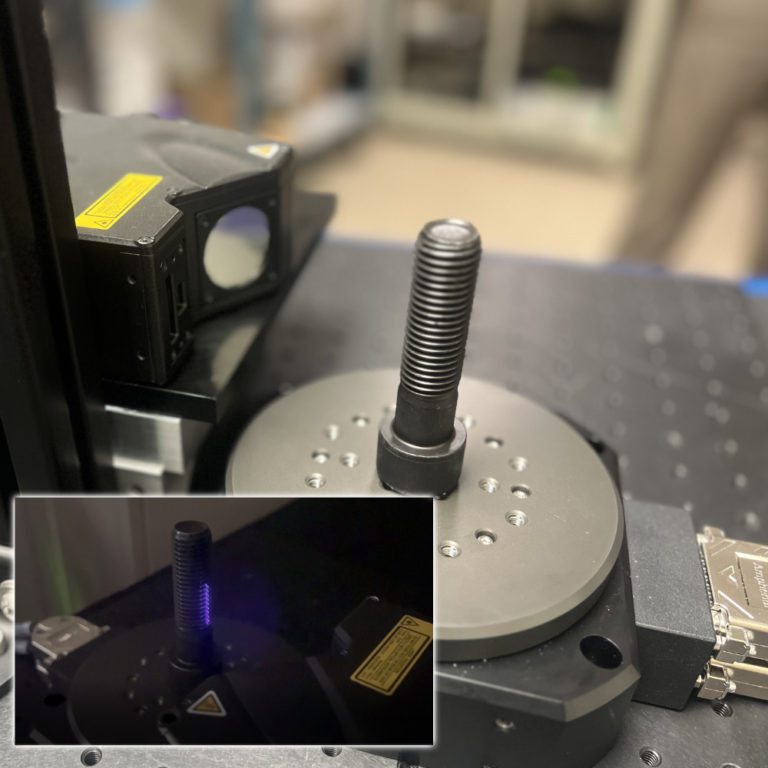

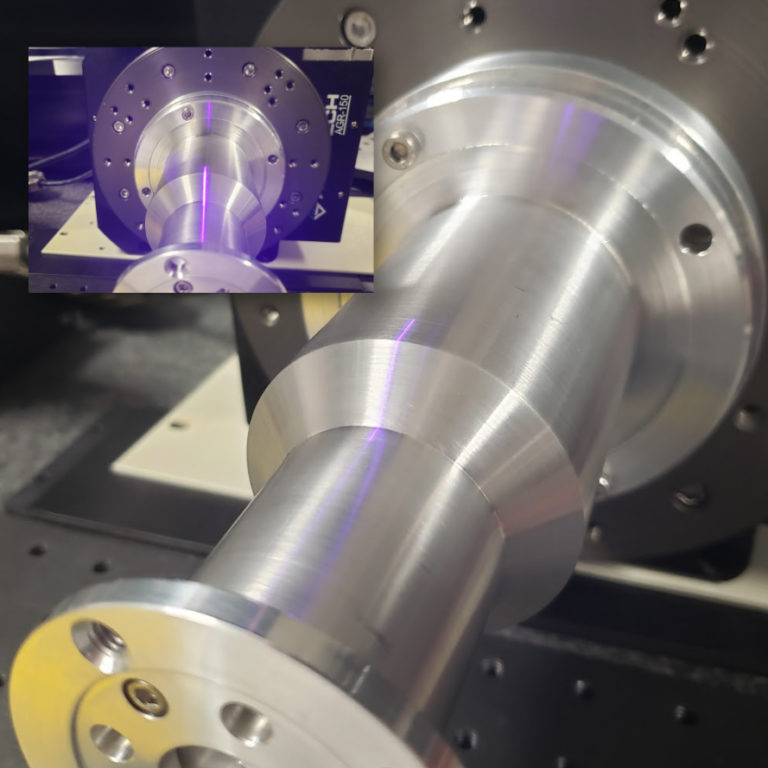

Back to back sensors

Remove the “shadowing” effect of laser triangulation sensors by using a second sensor.

- Available in "moving part" and "moving sensor" configurations

- Both sensors are mounted to the Peak provided bracket

- Both sensors are configured on one controller

Point sensors

The same scanning stages can be used with point sensors. Shown here is a CL sensor from Keyence.

- Adjustable arm is used to set the sensors focal height

- The stage motion triggers the data acquisition

- The output is a profile line of data

Demonstration video

See how easy it is to operate our scanning stages.

- Push a button

- Stage moves and triggers the sensor controller to take data

- Sensor controller displays measurement results

Scan/measurement definition process

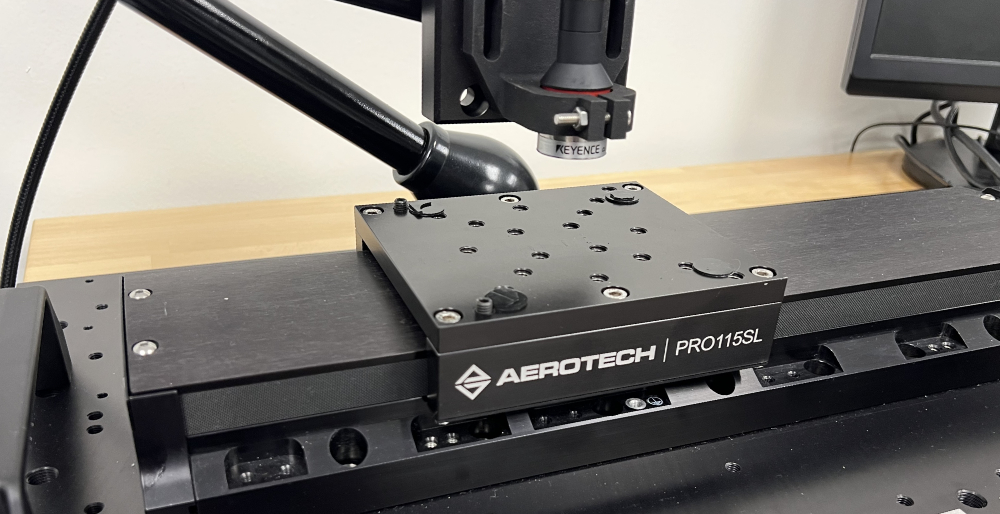

Linear motorized scanning stages

Use a program or push button interface to move your part in a straight line while scanning with the non-contact sensor.

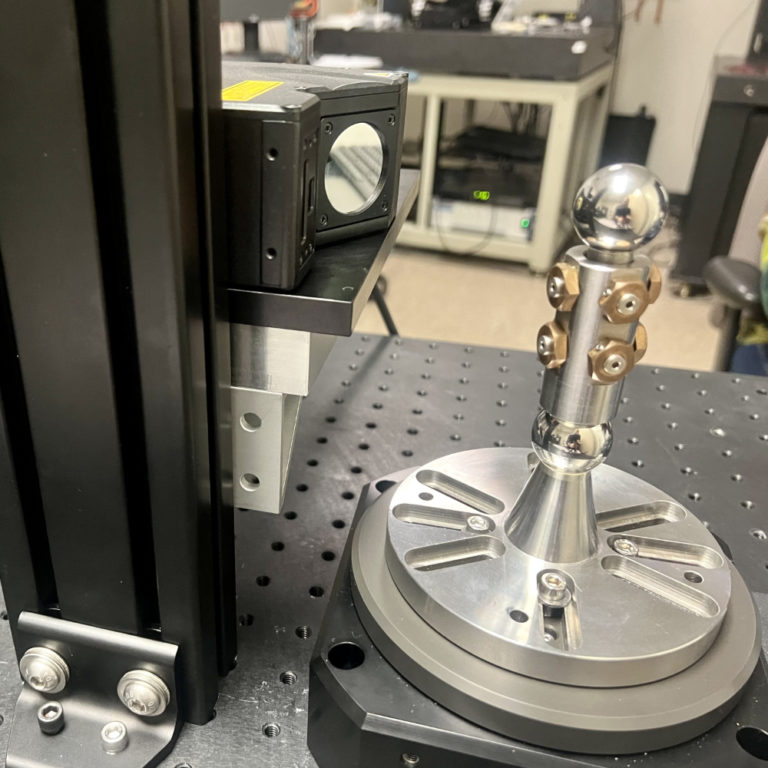

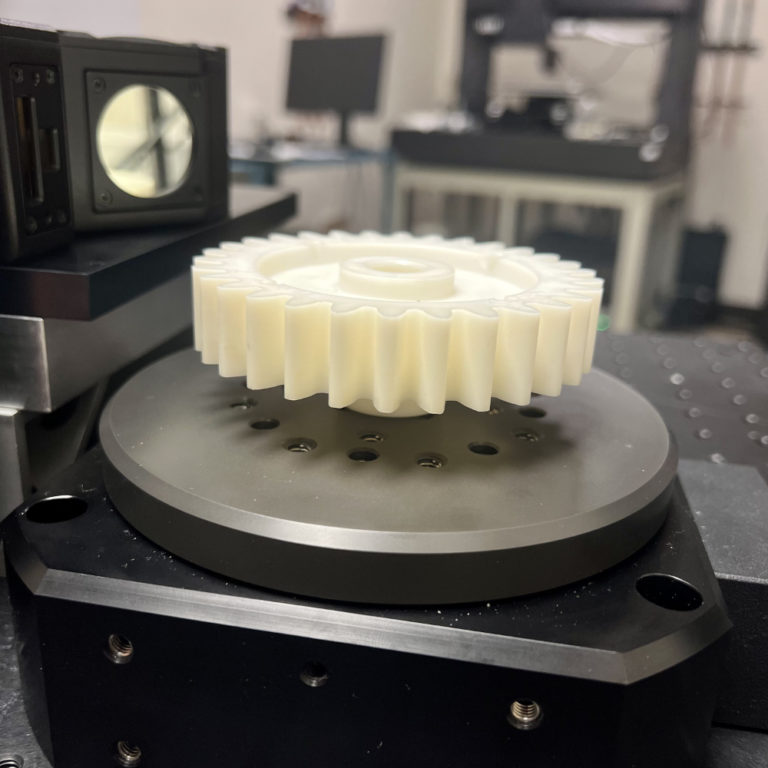

Rotary motorized scanning stages

Use a program or push button interface to rotate your part while scanning with the non-contact sensor.

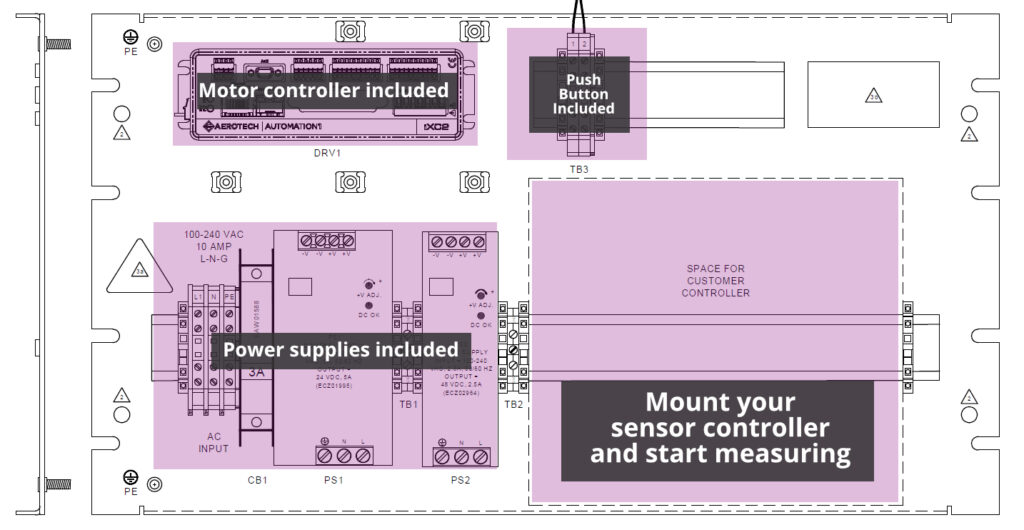

This scanning stage kit is ready to be paired with a sensor controller

We provide the remaining electronics and cables that you will need. Plug your sensor controller in and start taking scans.

- Pre-wired 19" common panel with all scanning stage components mounted

- Motor controller with encoder cable and push button

- Power supplies for both the motor controller and sensor controller

Installation video

Follow this step by step video to see how one of our stages is set up and configured for its first use. This is also accompanied by a user manual which will be delivered with the stage.

This video highlights the following topics:

- Shows a view of all of the equipment "out of the box"

- Shows the mechanical assembly of the kit

- Shows the electrical connections that a user needs to make

Additional Resources

Educational articles, white papers, and videos to help you make more informed decisions about your equipment purchases.

Help files, CAD downloads, and installation videos. Get in touch with your peak representative for the password.

Need more than a single stage?

Improved measurement capabilities are within reach.

Expand what your machine can do. Give your operators more tools and obtain a machine that is ready for the production floor.

Reasons you would need more capability

- You need to stitch individual scans together over a larger area

- Your operator process needs further simplified

- The machine needs to be integrated on the production floor