Part orientation and alignment are critical to automated microscopy applications. Whether you are trying to teach rotary stage positions for repetitive imaging, or if you need to clock parts for initial alignment, motorized rotary stages will help. Motorized rotary stages enable easier part alignment, more reproducible measurements, and less operator interaction.

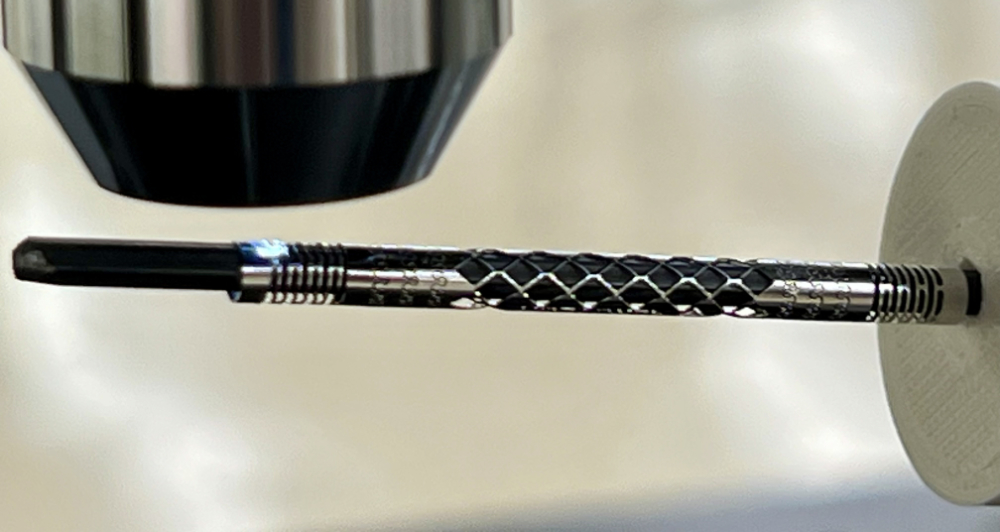

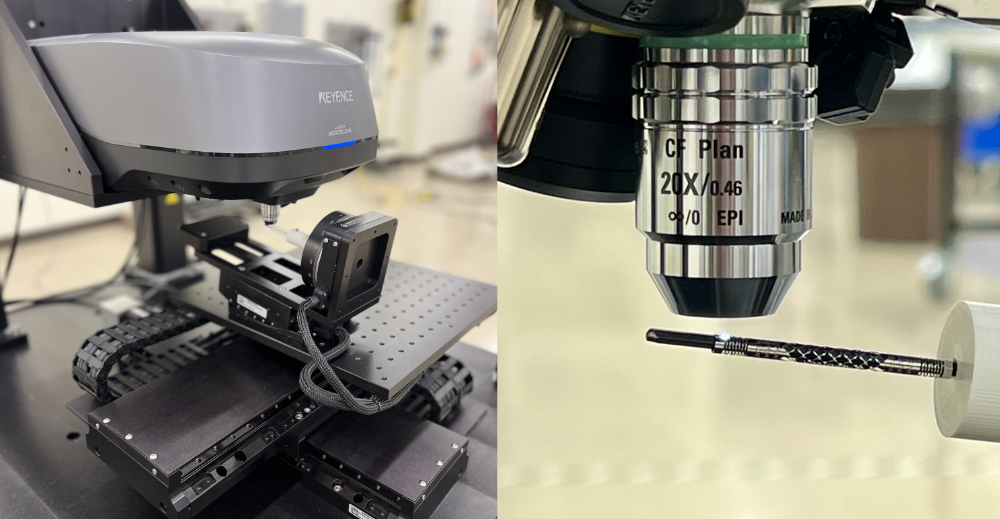

Showing a laser cut medical tube under a high magnification microscope objective.

Multi-Axis Rotary Stages

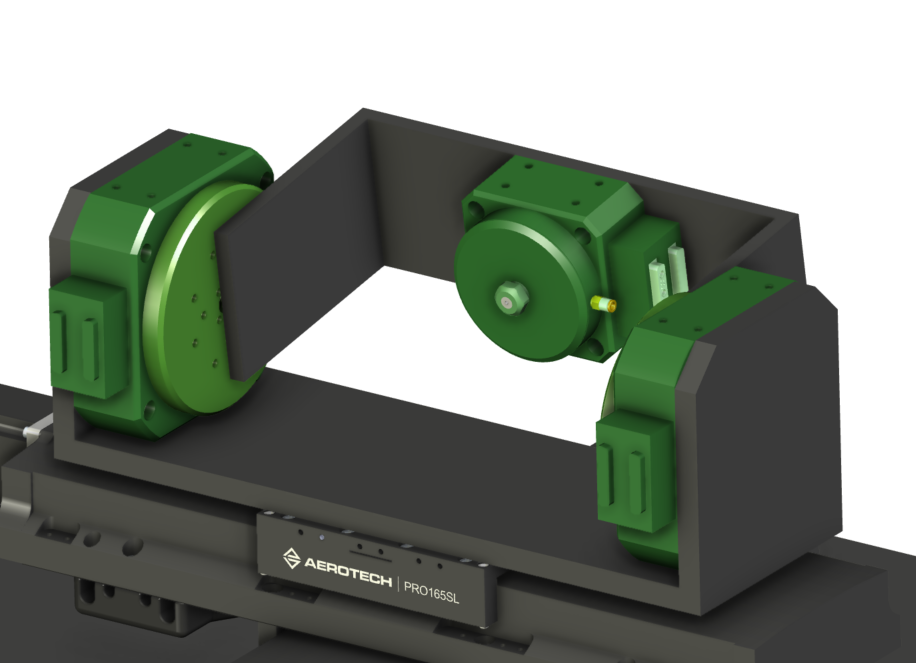

Through Aerotech, Peak Metrology offers a wide range of rotary stages with different travels, payload capacities, and orientations. We can control up to 3 rotary stages at a time. This means that orienting the part in more than one rotational direction at a time is possible. Furthermore, these rotary stages are motorized. Their position can be taught and recalled as part of a recipe program. This means repetitive part measurement can be automated.

Showing 2 rotary stages holding a stent on a mandrel. These rotary stages allow for reorientation of the stent so that it can be seen at different orientations under the microscope.

A 5-axis rotary stage is a common configuration for part orientation and alignment. Cylindrical parts can be easily inspected around their circumference, and the additional rotary axis allows for pitch adjustment. This allows for side wall or other vertical features to be viewed at an angle. This helps expose vertical features that would otherwise be difficult to view by a top-down microscope.

Showing a different configuration of 2 rotational stages. In this configuration, 2 rotary stages are controlled in unison to move a third rotary stage that has 360 deg of continuous travel to rotate the part.

See it in action

Below is a video demonstration showing the automated part rotation of a stent under a microscope using a 5 axis stage system. This system incudes XYZ stages plus an additional 2 rotation stages for 360 degree part rotation and pitch angle rotation.

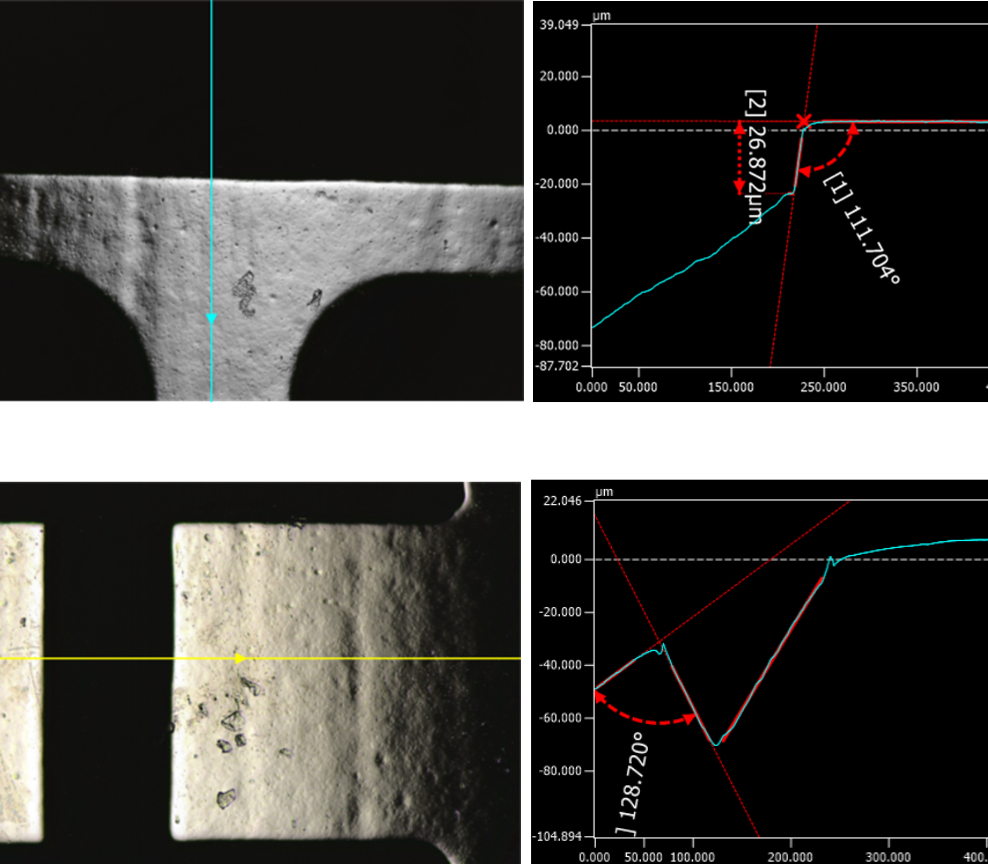

Application example: Stent Angle Measurement

Using the 5-axis stages allows for the stent to be positioned at orientations that make side wall angle measurement possible.

Showing the optical image of a stent profile and the corresponding side wall cut angles that are measured via profiles.

conclusion

Using motorized rotary stages allows for the positioning of samples under the microscope to be automated. This enables the automated measurement and inspection of hard to reach features on the surface of the part. Learn more about our Keyence VK-X capabilities here.

For more guidance and consultation please reach out to us. We offer full engineering and laboratory testing services to help guide our customers towards the right solution to their measurement challenge.